Our Crafting Process

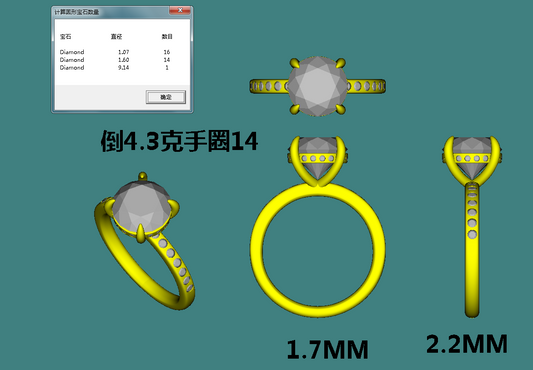

Stage 3: Stone Setting

Securely setting stones is crucial for their longevity.

Prepare the Seat: Holes are drilled into the setting, creating a secure "seat" for stones, particularly for side stones or hidden halos.

Create the Gallery: Drilling tools form a "gallery," optimizing sparkle by allowing light entry from the sides.

Setting Accent Stones: Stones are carefully pressed into their seats, with claws individually formed and pressed over each.

Set the Center Stone: The most valuable stone undergoes a secure setting, vital given its exposure to wear.